Author:Joes He

Interpreter:Paul Liu

PSI (CN) Inc. The automatic production schedule introduce

Pronology Services (China) Inc. is the professional EMS factory, our company major service is the require full system process service or PCBA OEM for some small business order quantity , PSI has various customers and products, and needs to switch production lines very often. Therefore, it is an important indicator to measure our profession by having a good production schedule control. ,PSI (CN) design an automatic production schedule which for their local own customers, that system will assist PSI (CN) to collect all of their customer information (kitting or ship date etc ) , We also used the “Daily schedule control” that will to advise the complete time and to hit the production target for our customer required !! PSI will keep update and organized the production schedule every day , also solve some of the customers problem. Our PSI supervisor will to check the production schedule immediately,

So we will explain to you that our PSI system function and instruction manual :

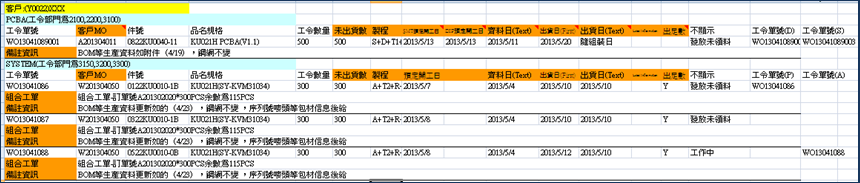

Please see below of PSI (CN) auto production schedule !! We had to explained each function and those data result is from our ERP and EMS system

| Field name | Field content | Field Description |

| 工號 Working Order |

WO21031070 | The working order number comes from which year,which month,Serial number and the manufacture process name |

| 批號 Lot No. |

1 | How many times One order will be divided into according to the Kitting date and shipping date |

| 組件件號 Parts No. |

0122KU0010-19 | According to the product type number(manufacture procedure Number+customer code+Model name) |

|---|---|---|

| KU021H(DS-11900) | model name from the customer | |

| 客戶P/O Customer P/O |

customer order(In future,customers can to review the production schedule by P/O No. in PSI' MES system | |

| W201303032 | MO | |

| 工令量 Quantity |

100 | Lot size(quantity of order) |

| 100 | The balance quantity after the first time shipment(it will be updated by ERP directly | |

| 排產量 Required |

100 | Fill in the quantity by manual according to the demand of the customer |

| XXXX | customer's company name | |

| 缺料 Shortage |

NO | To show the Working Order whether shortage material or not by ERP automaticly,the frequency just one time per day |

| 4/26 | the start date will be arranged according to the Material kitting date | |

| 預定完工日 Complating Day |

5/10 | the delivery date |

| 線別 Line Name |

3301 | (Here is the Line name, PSI have four SMT lines and two DIP lines and tow package lines.PMC will arrange production according to the lines and manpower. |

| 工序 Process |

7 | This item shows the production sequence, we arrange the order sequence according to the kitting date and the delivery date |

| 線別+工序 Line Name + Process |

3301007 | line name + production sequence |

| 標準工時(分) Standard Time(minutes) |

0.8 | Bottleneck of working time |

| 準備時間(H) Setup Time(H) |

0.5 | lead time for change the model |

| 工時小計(H) Working Hours(H) |

2 | We can figure out how long we will spend in finishing the volume of production:(the volume of production)*Standard Time + Setup Time |

| 中午前置時間(H) Lead Time at noon(H) |

0 | Rest time at noon |

| 下午前置時間(H) Lead Time in the afternoon(H) |

0 | rest time in the afternoon |

| 下午前置時間(H) Lead Time in the afternoon(H) |

0 | Overtime |

| 總耗時(H) Total time(H) |

2 | Working Hours + rest time at noon + rest time in the afternoon + Overtime=Total time |

| 開始時間 Starting Time |

2013/5/4 13:00 | the Start Time of an order |

| 結束時間 Ending Time |

2013/5/4 15:00 | the ending Time of an order(equal to the total time) |

| QC 機台 QC Equipment |

出貨日: 5/10 | we can note some important information such as the inspection date and the shipping date |

| DIP首件產出時間/數量 The Date or Quantity of The DIP First Piece |

2013/5/10 | The date or quantity of the DIP first piece base the DIP starting time |

| 出貨日(Text) Shipping Date (Text) |

accoding to the salesman's everyday message | |

| 製程 Manufacture Process |

A+T2+R+P | manufacture procedure such as S+D+T1+A+T2+P |

The PC will follow the firm orders and base on sales , shipping schedule and WIP stock to arrange the 2~3 days for the production, The schedule will also base on production line working hours and calculates finishing date , PC will update the production schedule each morning , All the data will came from the MES system for the production line schedule (pic 4), and make sure we meet the reach of the PC target, we will to discuss and communicate that if have any problem, if the production can’t reach of the target which the production line need to review it !!

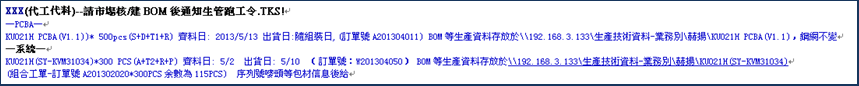

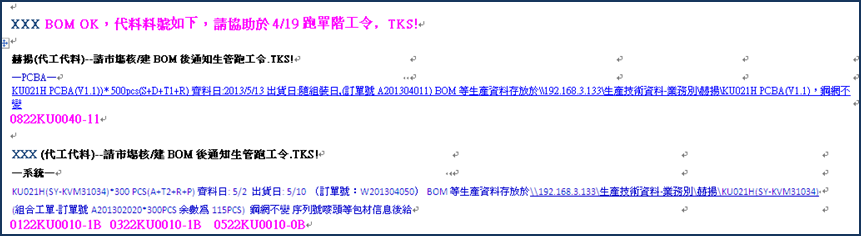

When our sales receive the new purchase order from the customer, PSI (CN) will create the new purchase order as below :

The marketing dep. staff will create and inspect for our customer BOM base on the notice from the sales ,the marketing dep. will also create the new bom in PSI (CN) ERP system, if those working order is not first time to production, the system will run the previous BOM and new BOM for compare the different between each other, then the marketing dep. will provide the main part number to PSI production to create for the W/O Number

The PC will create a Working Order No. in ERP system , and PC will create the W/O base on what’s the sales provide to them , That afternoon sales will create a material file in the ERP system which will be used by the PC for production schedule.

【Picture 1-Sales Order】

【Picture 2-Shipping schedule】

【Picture 3- WIP Stock】